- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 751 Author: Site Editor Publish Time: 2022-07-14 Origin: Site

Stranding is the process of twisting multiple small diameter monofilaments into large cross-sectional conductive cores according to specific rules.

The type of stranding process: stranding has two types normal stranding and rare stranding.

Normal stranding

Normal stranding can be divided into average concentric single strand stranded and normal concentric stranding.

1. Normal stranding: single-stranded wire of the same diameter is stranded regularly in concentric circles layer by layer, each layer in the opposite direction.

2. Stranded: by the same diameter, different materials or different diameters, different materials of single-stranded wire (such as overhead wires).

Normal concentric stranding: a stranded wire made of multiple strands of ordinary stranded wire or bundle wire stranded concentrically.

Irregular stranded (stranded wire)

Stranded wire is formed by multiple single strands in the same direction and is not in compliance with the stranding rules. The position of the single strands is not fixed, and the shape of the strands is challenging to maintain in a round shape.

The difference between stranded wire and ordinary stranded wire

Ordinary stranded wire has a fixed position for every single strand and is stranded regularly layer by layer; bundled monofilaments do not have a fixed position between them and are not stranded together according to the stranding law.

Characteristics of irregular stranding (bundle)

Because each monofilament in the bundle is a one-way twist, bending between each monofilament sliding margin, resistance to bending is small, so the bundle's bending performance is excellent. For wire and cable products that require soft and frequent movement, bundles are used as conductor cores.

Stranded iron core features

1. good flexibility: using multiple smaller diameter single wires composed of the core can improve the bending resistance of the cable, easy to wire and cable processing, manufacturing, installation, and laying.

2. good stability: by a number of a single wire in a specific direction and stranding rules stranded into the core, because every single wire in the stranded position in the upper part of the stranded elongation zone and the lower part of the compression zone will be pulled out of the stranded wire in turn, the stranded wire bending will not be deformed.

3. Good reliability: Wire and cable using a single wire as a conductor, easy to uneven material or stranding defects and affect the reliability of the conductor core. The defects of the conductor core formed by multiple single wires are scattered and not concentrated in one point of the conductor. Hence, the reliability of the conductor core is much stronger.

4. High strength: The strength of a single-stranded core is higher than that of a single-stranded core.

Terms used in the stranding process

1. Pitch: The distance that a single wire moves axially for one week.

2. Pitch ratio: The ratio of the pitch length of the strand to the diameter of the strand.

3. pitch and strand softness relationship: the smaller the pitch, the better the flexibility of the strand. The larger the pitch, the less flexible the strand.

4. stranding factor: the ratio of the actual length of single strand expansion to the length of the pitch in a stranded pitch.

5. strand direction: right (z) left (s direction)

6. Compression conductor: common tightly compressed conductors are tightly compressed round, fan-shaped, and tile (five-core cable), semi-circular (two-core cable)

Why tighten

1. compact compression fan-shaped conductor: reduce the outer diameter of the cable, save product cost and reduce the weight of the cable.

2. Compact compression round conductor: improve stranded conductor surface quality, reduce conductor diameter, improve conductor filling factor, smooth and round conductor surface after tight compression, uniform conductor surface electric field. Save material and reduce cost.

Classification of conductors

According to GB/T3956 cable conductors, there are four types of conductors: type 1, type 2, type 5, and type 6. The first is a solid conductor; the second is a stranded conductor, which is suitable for fixed laying cables; the fifth and sixth are stranded conductors for flexible cables and flexible wires, and the sixth is softer than the fifth.

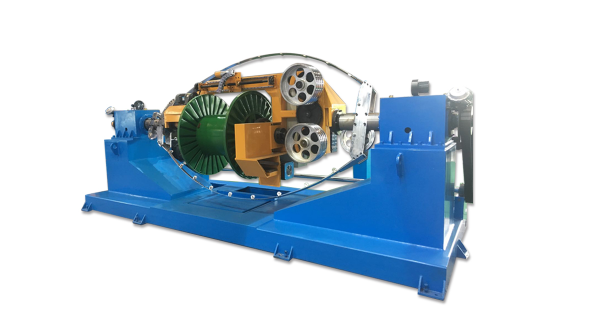

Taizheng, a professional wire harness production equipment supplier, provides all kinds of wire harness production machines, including Twist Stranding Machine, Twist Bunching Machine, Plastic Extrusion Machine, Coiling Machine, etc.