- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 13 Author: Site Editor Publish Time: 2023-07-28 Origin: Site

In the world of wire cable production, the demand for custom solutions is constantly growing. Each industry has its unique requirements when it comes to wire and cable products, making it essential for manufacturers to be able to adapt and customize their machinery accordingly. This is where the importance of customization and adaptability in wire cable twisting machines comes into play. This blog post will explore the significance of tailoring these machines for specific applications and how they can revolutionize the wire cable industry.

No two industries are the same, and the wire cable industry i

s no exception. From automotive to aerospace, from telecommunications to oil and gas, each sector has distinct specifications and regulations that must be met. This is where customization becomes crucial. Generic twisting machines may need help to meet the unique demands of each industry, resulting in compromised quality and efficiency. By tailoring wire cable twisting machines to specific applications, manufacturers can ensure that their products are manufactured to the highest standards, optimizing performance and reliability.

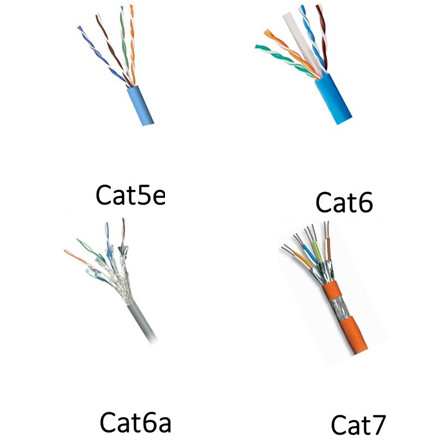

Wire cables come in a variety of types, sizes, and materials. Examples include copper, aluminum, fiber optic, coaxial, and ribbon cables. Each cable type requires a different approach to twisting and braiding. Customizable wire cable twisting machines can have the necessary configurations and tooling to handle other wires effectively. This adaptability allows manufacturers to efficiently produce a wide range of cable products, catering to diverse customer needs.

Customization in wire cable twisting machines extends beyond adapting to different cable types. Manufacturers often have specific machine dimensions, speed, tension, and control systems requirements. Customization allows for incorporating these preferences, creating machines that align perfectly with the manufacturing process. Manufacturers can streamline their operations, eliminate bottlenecks, and increase productivity by tailoring machine configurations to specific applications.

Quality control is paramount in the wire cable industry, as faulty cables can lead to disastrous consequences. Customizable wire cable twisting machines can incorporate advanced inspection and testing systems to ensure each line meets the required standards. From real-time monitoring of parameters such as tension and diameter to automated rejection of defective cables, these machines provide manufacturers with the tools to maintain uncompromising quality control. With customization, manufacturers can even integrate their quality control processes into the twisting machines, further enhancing the accuracy and reliability of their cable production.

Contrary to popular belief, customization only sometimes equates to higher costs. Tailored wire cable twisting machines can provide significant cost-efficiency and time savings in the long run. Manufacturers can minimize material waste, reduce downtime, and increase production speed by optimizing the machine's capabilities for specific applications. Additionally, the ability to adapt and customize devices allows for easier integration into existing manufacturing lines, eliminating the need for extensive modifications or replacements. This saves costs and accelerates the production process, allowing manufacturers to meet tight deadlines and stay competitive in the market.

As technology advances, the potential for customization and adaptability in wire cable twisting machines is boundless. Machine learning capabilities can be integrated to analyze data and optimize machine settings for specific cable types. Internet of Things (IoT) connectivity can enable remote control and monitoring of machines, providing real-time insights and troubleshooting capabilities. The possibilities are immense, and manufacturers who embrace customization and adaptability will be at the forefront of innovation in the wire cable industry.

Customization and adaptability are vital factors in ensuring the success of wire cable manufacturing in diverse industries. By tailoring wire cable twisting machines for specific applications, manufacturers can meet the unique requirements of each sector, optimize productivity, and enhance quality control. The ability to adapt to different cable types, flexible machine configurations, and the resulting cost-efficiency and time savings make customization an indispensable asset in the wire cable industry. As technology continues to evolve, the possibilities for customization and adaptability are becoming limitless, promising a future of groundbreaking advancements in wire cable production.

If you are interested in further exploring the world of wire cable twisting machines, be sure to connect with leading manufacturers and experts in the field. They can provide valuable insights, recommendations, and solutions tailored to your wire cable needs. Embrace customization and adaptability, and watch your wire cable manufacturing soar to new heights.