- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 44 Author: Site Editor Publish Time: 2024-01-08 Origin: Site

In the intricate electronic and power systems world, cables play a pivotal role. The diversity and complexity of Cable Structures are immense, catering to a broad spectrum of applications across various sectors. This article aims to demystify different types of cable structures, shedding light on their unique characteristics and applications. Understanding these distinctions is crucial for cable equipment manufacturers and users who rely on these essential components in their daily operations.

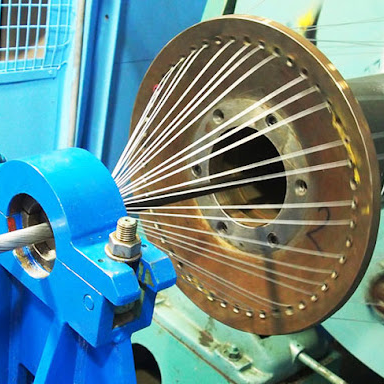

The construction of a cable is a sophisticated engineering feat involving several vital components that define its performance and suitability for specific applications.

Conductor: The primary pathway for electrical signals or power, usually made of copper or aluminum for optimal conductivity.

Insulation Layer: This component surrounds the conductor, providing electrical insulation and preventing short circuits. Materials like PVC, polyethylene, or Teflon are commonly used.

Shielding Layer: In many cables, a shield layer helps protect the signal from electromagnetic interference, ensuring data integrity, especially in communication cables.

Protective Outer Sheath: The external layer that protects the internal components of the Cable from environmental factors like moisture, chemicals, and physical damage.

Understanding these components is essential for users and cable equipment manufacturers as it helps select the suitable Cable for the intended application.

Structure Features: Consists of a central conductor, an insulating layer, metallic braiding or foil shielding, and an outer protective layer.

Main Application Areas and Advantages: Extensively used for television signal transmission, internet connectivity, and high-frequency data communication, known for its superior shielding and reduced signal interference.

Structure Description: Features pairs of insulated wires twisted together. It is differentiated into Shielded Twisted Pair (STP) and Unshielded Twisted Pair (UTP).

Distinction and Uses: Widely used for network cabling and telephone lines, where STP provides additional protection against electromagnetic interference, UTP is commonly preferred for its cost-effectiveness.

Structural Details: Composed of a central glass or plastic fiber core surrounded by a protective layer and sheathing.

Main Uses and Advantages: Known for high-speed data transmission capabilities, especially in long-distance and high-bandwidth applications, offering superior performance over traditional cables.

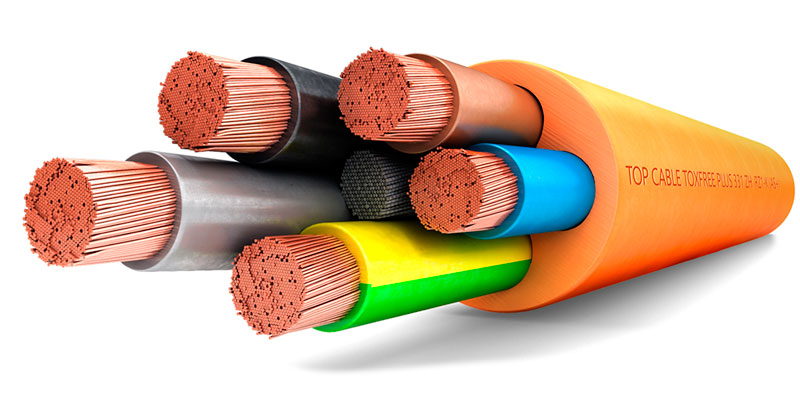

Structure Composition: Contains multiple independently insulated conductor cores.

Scenarios and Performance Characteristics: Essential in applications requiring numerous signals or power paths, such as in power transmission, control systems, and complex machinery.

Structure Description: Comprised of multiple wires running parallel to each other in a flat, ribbon-like formation.

Typical Uses: Often used when space saving and flexibility are essential, such as in computer and electronic equipment internal connections.

Structure Features: Contains one or more conductors covered by a metallic shield layer designed to reduce electromagnetic interference.

Functionality: Crucial in environments where interference can disrupt signal integrity, such as in data and communication systems.

Structure Analysis: Features additional metal armor for physical protection on top of the standard cable structure.

Application Areas: Used in environments where cables are exposed to mechanical threats or harsh conditions, providing enhanced durability and protection.

Structure Explanation: Multiple wires bunched or twisted together may or may not be individually insulated.

Characteristics and Uses: Useful in applications where flexibility and ease of handling are priorities, including various industrial and electronic contexts.

Structure Composition: Consists of one or more conductors, a thick insulation layer, and a protective outer sheath for electricity transmission.

Key Role in Power Transmission: Fundamental in delivering electrical power in buildings, infrastructure, and various industrial applications.

Selecting the appropriate cable type is crucial for the efficiency and safety of any electrical or data transmission system.

Application Requirements: Understand the specific needs of your project, whether it's for power transmission, data communication, or other purposes.

Environmental Conditions: Consider factors like exposure to moisture, chemicals, extreme temperatures, and physical stress, which can influence the choice of Cable.

Regulatory and Safety Standards: Ensure the chosen Cable meets industry standards and safety regulations applicable to your project.

Consulting with cable equipment manufacturers or specialists can provide valuable insights.

Reviewing technical specifications and performance data helps in making an informed decision.

Proper installation and regular maintenance are critical to the longevity and performance of cable systems.

Follow manufacturer guidelines and industry best practices to ensure correct installation.

Pay attention to aspects like cable routing, connections, and shielding effectiveness.

Regular inspections for signs of wear, damage, or environmental impact.

Timely replacement or repair of defective sections to prevent system failures.

The cable industry continually evolves, with innovations enhancing performance and expanding possibilities.

Advanced Materials: Research in new materials is leading to cables that are more durable, flexible, and capable of handling higher data rates or power loads.

Smart Cable Technologies: Integration of sensing and monitoring capabilities for real-time performance tracking and diagnostics.

Sustainability Focus: Increased emphasis on eco-friendly materials and production processes.

Enhanced Data Transmission Capabilities: Ongoing improvements in fiber optic and high-speed cable technologies to meet the growing demands of data centers and communication networks.

Cables are the lifelines of modern technology, playing a crucial role in everything from everyday electrical applications to sophisticated data centers and communication networks. Understanding the various types of Cable Structures and their applications is essential for choosing the suitable Cable for specific needs. As technology advances, so do the capabilities of cables, driven by innovation and a commitment to quality by cable equipment manufacturers. Staying informed about these developments is critical to leveraging their full potential and ensuring the success of your projects.

Encouraging a deeper understanding of cables can lead to optimized applications and advancements in efficiency and technology.