- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 405 Author: Site Editor Publish Time: 2021-12-13 Origin: Site

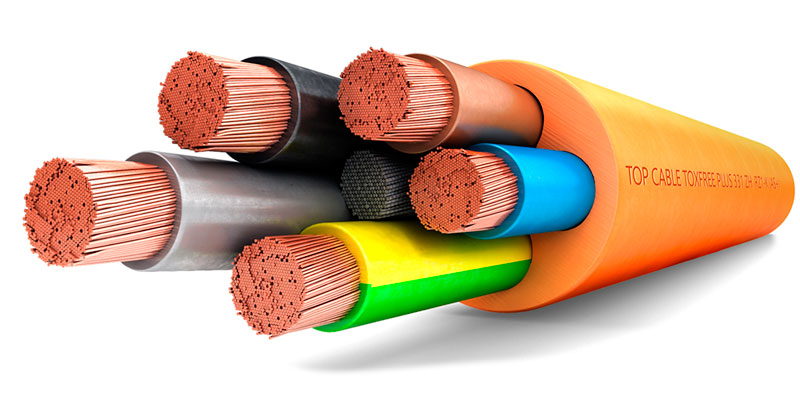

Modern industry has purified and treated some of the halogen elements in cable production, and low smoke zero halogen cable, lszh cable are more stable, and have good basic functions of fire prevention and heat insulation, and are suitable for various conditions.

LSZH cable is especially used in subway stations, nuclear power plants and many computer industries.

1. Suitable for low smoke zero halogen wire.

This product is suitable for subways, high-rise buildings, shopping malls, theaters, power stations, chemical plants, city squares and other public utilities with AC rated voltages of 450/750V and below. High occasions. The cable has the characteristics of halogen-free, low-smoke, low-halogen and low-smoke. In the event of a fire, the diffusion speed is slow, the smoke concentration is low, the visibility is high, and the release of harmful gases is small, which is convenient for evacuation. The combustion gas is less corrosive, and equipment damage is also avoided. The characteristics of low halogen and halogen-free greatly improve the anti-aging, anti-ultraviolet and other radiation capabilities of the cable material, thereby prolonging the service life of the cable.

2. Low smoke zero halogen cable features.

(1) The tensile strength is greater than that of ordinary PVC wires: the tensile strength of ordinary PVC wires is greater than 1.05Kgf/mm2, and the smoke and halogen-free wires and cables are greater than 1.2Kgf/mm2,

(2) It has good weather resistance (-30℃~105℃) and flexibility (hardness 80-90),

(3) No migration, because this product formula does not need to add plasticizers, so the shape will not migrate

(4) It will not produce toxic black smoke (a small amount of white smoke will be produced) when burning, and has a high volume resistivity: usually use PVC wire 12

(5) It has 1012~1015Ω/cm3, and the zero halogen cable is greater than 1016Ω/cm3, (5) It has good high voltage resistance: PVC wires generally can withstand more than 10KV, and lszh cable ≤ 15KV

(6) It has good elasticity and viscosity, and is non-toxic: lszh cable uses special material M without PVC material. No toxic gas is produced during the combustion process.

(7) Pollution-free: no lead, cadmium and other heavy metals, residues will not cause damage to the soil environment; non-corrosive: no toxic gas such as hydrochloric acid is produced during the combustion process, and the acidity is very small.

(8) High light transmittance: lszh cable treated with a special process will produce less smoke when burned. The product standard stipulates that the light transmittance is greater than 60%.

(9) Anti-ultraviolet rays: The special structure of low smoke zero halogen cable makes it resistant to strong ultraviolet radiation.

Now, the photovoltaic clean energy market adopts special low smoke zero halogen cable products. Choosing lszh cable to improve the safety and quality of the environment is a type that is particularly commonly used in many high-end buildings. Therefore, in order to ensure the selection of truly high-quality products, we must pay attention to brand guarantees to truly achieve safe use. The effect can truly meet the actual needs, and it is also a necessary condition for selecting the focus of the method.

Equipment required to produce cable:

TZ-BM300 double twist bunching machine → for conductors if using stranded 7 x 0.145 mm(0.12 mm2 /26AWG).

TZ-EP50+35 extruder line → for conductor insulating using HDPE/PE of 4 colours (as required with stripes).

TZ-ET35+60+40 physical foaming extrusion line → for conductor insulating using skin-foam(SF)/skin-foam-skin(SFS) technology.

TZ-PT500 pair twist+back twist machine → for each single pair twisting with back twisting purpose.

TZ-SC800 cantilever single twisting machine → for 4 pairs cabling along with universal Alu foil screening or single pair Alu foil screening or both+ripcord/separator filling.

16 carriers braiding machine → for inner shielding of tinned copper/Mg-Al wire with Alu foil screening.

TZ-EP70(+50) extruder line → for outer jacket sheathing of PVC (or dual layer jacketing of PVC+LSZH).

TZ-CE400 Ethernet cable cross figure coiling machine → for finished ethernet cable coiling 1000 feet/reel (can be online with jacketinig line).