- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 34 Author: Site Editor Publish Time: 2022-08-17 Origin: Site

If you want to open a cable, wire harness manufacturers, cable production equipment is essential, and there are many types of cable production equipment. If you are the first time to get involved in this industry, then how to buy the right equipment should be a significant headache for you. Cable equipment manufacturer Taizheng will share with you through this article, wire drawing machine and stranding machine the two kinds of the equipment buying guide, hope to help you better choose the right equipment.

Wire drawing machine

Wire drawing machine equipment, also known as metal drawing equipment, is roughly divided into large wire drawing machines, medium-sized wire drawing machines, small wire drawing machines, and fine wire drawing machines.

The wire material can be divided into different pages: stainless steel wire drawing machine, copper wire drawing machine, copper clad steel wire drawing machine, copper clad aluminum wire drawing machine, copper clad copper wire drawing machine, cutting wire drawing machine, enameled wire drawing machine and other wire drawing equipment.

What do you need to provide?

Buyers only need to provide three kinds of data.

1. the material of the copper rod, such as copper or aluminum, is divided into a copper wire drawing machine and an aluminum wire drawing machine.

2. The copper rod's diameter and the finished wire's diameter. These two data will determine the model of the wire drawing machine.

3. some accessories, such as wire release and take-up. On the one hand, the manufacturer can recommend, but it is also recommended to make your requirements.

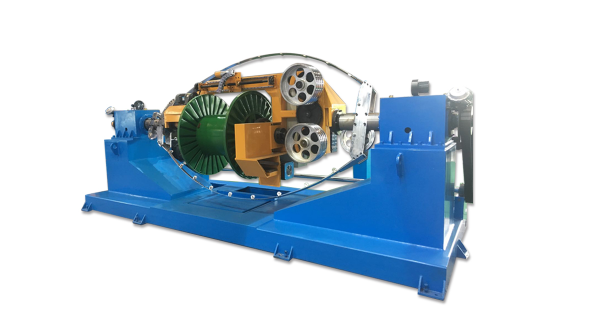

Stranding machine

The stranding machine is also divided into copper, aluminum, and steel wire stranding machine is the most critical machine in the cable manufacturing industry and is an essential step in production. It's good or bad has a direct impact on the quality of the cable, which is also a device of great concern to cable manufacturers.

What do you need to provide to buy a stranding machine?

1. the material of the thread and the construction of the thread. For example, if producing 19 lines, its structure should be 1+6+12. If changing lines with 37 lines, its structure should be 1+6+12+18. Here the structure refers to the innermost central thread, the second layer of 6 threads, and the third layer of 12 threads. Know the structure of the line to know the structure of the machine.

2. The diameter range of the wire. In general, the rigid stranding machine mainly produces 1mm-5mm mm wire. Due to the high toughness of the wire, you can expand the wire diameter range.

3. the size of the wire reel in the stranding cage, such as PN400/PN500/PN630/PN710. Most plants use 500 and 630-type reels.

4. some mills need to produce shaped conductors when stranding copper and aluminum wires. The supplier will be notified in advance and will add a rotary compression device to accommodate the production of shaped conductors.

5. The size of the bobbin for wire release and take-up. The common ones are PN500/PN630/PN800/PN1250/PN1600/PN2000/PN2500, etc.

The primary forms of take-up and payoff are end-shaft type and gantry type.

6. The form of loading barrel tube is mainly divided into manual, side bottom 45°, and side-lying type. Among them, manual loading cost is low. General production 54 lines use the side type.

To purchase the proper cable equipment, you first and foremost need to find a reliable manufacturer because of the strength and credentials of the manufacturer to recommend the most suitable cable production equipment for you based on your needs and the information you provide if you need to purchase cable equipment, welcome to leave a message or contact us.