- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

The bunching process can be explained as follows:

Various wires coming into a high speed double twist copper wire buncher which will be in charge of assembling them into a bunch or a strand.

The phase stranding process consists of assembling some strands or cables for the construction of a multi-conductor cable. Depending on the shape of its cross section, this process can be called round stranding or sectoral stranding.

These 2 processes can be carried out either with flexible or rigid and either with bare or insulated conductors

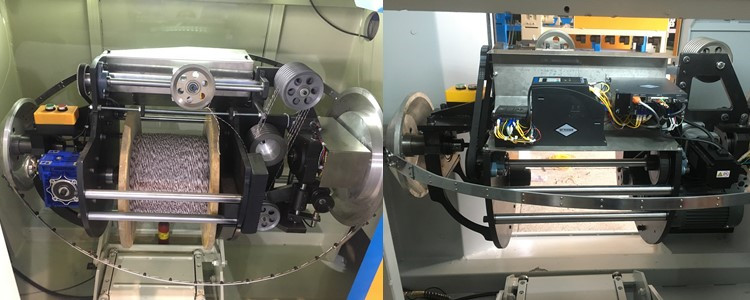

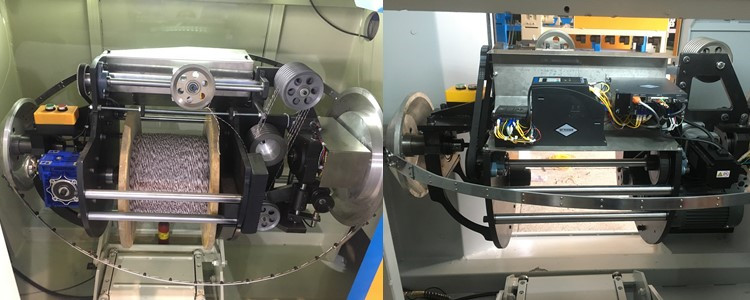

The model BM-500S and BM-630S is the latest technology with following characteristic:

Higher Speed by using larger level main drive

Laying pitch change by capstan gear or HMI and displayed at touch screen

Using servo motor for traversing unit with more stable performance

Both models are using motorized reel lifting instead of convetional hydraulic lifting

The bunching process can be explained as follows:

Various wires coming into a high speed double twist copper wire buncher which will be in charge of assembling them into a bunch or a strand.

The phase stranding process consists of assembling some strands or cables for the construction of a multi-conductor cable. Depending on the shape of its cross section, this process can be called round stranding or sectoral stranding.

These 2 processes can be carried out either with flexible or rigid and either with bare or insulated conductors

The model BM-500S and BM-630S is the latest technology with following characteristic:

Higher Speed by using larger level main drive

Laying pitch change by capstan gear or HMI and displayed at touch screen

Using servo motor for traversing unit with more stable performance

Both models are using motorized reel lifting instead of convetional hydraulic lifting

Machine model | BM-500S | BM-630S | |

| Inlet | Core (mm) | 2-4 core, 0.5-1.2 | 2-5 core, 0.5-1.6 |

Conductor (mm) | ≥7, 0.08-0.64 | ≥7, 0.08-0.64 | |

| Finished | Core (mm) | OD max.4.0 | OD max.4.5 |

Conductor (mm2) | Max 2.5 | Max 6.0 | |

| Suitable Materials | Core (PVC,PE insulated) & Conductor (CU/TC/CCA/CCS/ALU/Enamelled wires etc) | ||

Lay direction | Left or Right (S or Z) | ||

Lay length change | By HMI touch screen | ||

| Spool size(mm) | ¢500x300x56 | ¢630x475x56 | |

Rotation speed(rpm) | 3000 | 2500 | |

Line speed. Max | 180m/min | 220m/min | |

Machine model | BM-500S | BM-630S | |

| Inlet | Core (mm) | 2-4 core, 0.5-1.2 | 2-5 core, 0.5-1.6 |

Conductor (mm) | ≥7, 0.08-0.64 | ≥7, 0.08-0.64 | |

| Finished | Core (mm) | OD max.4.0 | OD max.4.5 |

Conductor (mm2) | Max 2.5 | Max 6.0 | |

| Suitable Materials | Core (PVC,PE insulated) & Conductor (CU/TC/CCA/CCS/ALU/Enamelled wires etc) | ||

Lay direction | Left or Right (S or Z) | ||

Lay length change | By HMI touch screen | ||

| Spool size(mm) | ¢500x300x56 | ¢630x475x56 | |

Rotation speed(rpm) | 3000 | 2500 | |

Line speed. Max | 180m/min | 220m/min | |