- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 933 Author: Site Editor Publish Time: 2023-02-08 Origin: Site

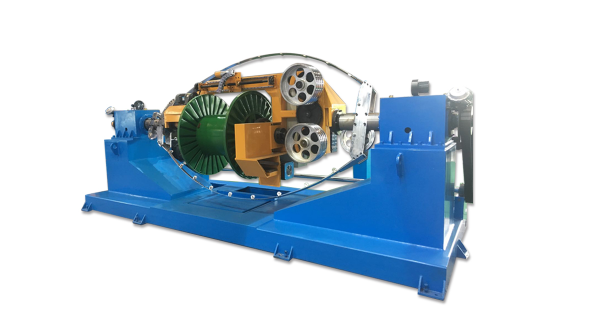

A bunching machine is a type of machine used in the manufacturing industry to produce cable and wire products. The process involves twisting individual wires together to form a bunch or bundle, which can then be used as a conductor of electrical energy. The machine is a critical component in the production of electrical cables and wire and is commonly used in the manufacture of power cables, data cables, and other types of electrical wiring.

Bunching machines come in various sizes and capacities, depending on the type and size of the wires being processed. They can be classified into two types: stranding machines and taping machines. Stranding machines are used to twist together several wires to form a bundle while taping machines are used to wrap an insulating material around the bundle. Both types of machines can be further classified into single twist, double-twist, and planetary twist machines, depending on the twisting method used.

The bunching process is a crucial step in the production of electrical cables, as it determines the strength and conductivity of the final product. The twisting process involves twisting individual wires together, either by hand or by machine, to form a bunch or bundle. The resulting bundle is then either coated with an insulating material or used as-is in certain applications. The tightness of the twisting and the number of turns per unit length determine the electrical and mechanical properties of the bunch.

Bunching machines are designed to produce bunches with a consistent and uniform twist, which is essential for producing high-quality electrical cables. The machine is typically equipped with a series of spools that hold the individual wires in place, while a rotating twisting mechanism twists the wires together. The twisting mechanism can be adjusted to produce the desired number of turns per unit length, and the machine can be programmed to stop at a specific length.

In addition to the twisting mechanism, bunching machines also typically include a control system that monitors and regulates the twisting process. The control system can be programmed to adjust the twisting speed and direction, as well as to stop the machine at a specific length. This allows the operator to produce bunches with consistent electrical and mechanical properties, regardless of variations in wire size or material.

Bunching machines are widely used in the electrical cable and wire industry due to their efficiency, accuracy, and versatility. They can be used to produce a wide range of bunches with different electrical and mechanical properties, depending on the type and size of the wire being processed. The machines are also relatively easy to operate and maintain, which makes them ideal for use in both small and large manufacturing operations.

In conclusion, the bunching machine is a critical component in the production of electrical cable and wire and plays a key role in determining the strength and conductivity of the final product. The machine is highly efficient, accurate, and versatile, making it an essential tool for manufacturers in the electrical cable and wire industry. With advances in technology and design, bunching machines are becoming even more reliable and user-friendly, making it easier than ever for manufacturers to produce high-quality electrical cables and wires.

If you are looking for bunching machine, welcome to contact Taizheng Machinery, we are experienced bunching machine manufacturer, can provide you with high-quality, cost-effective equipment.